Hydraulic shearing machines are essential tools in various industrial settings, specifically used for cutting sheet metal with precision and efficiency. These machines are a cornerstone used in sheet metal fabrication shops, automotive industries, and manufacturing units. Central to their operation are the shear blades, which play a critical role in determining the accuracy and quality of the cutting. Shear blades in hydraulic shearing machines slice through metals with minimal deformation. This ensures clean and precise cuts every time. The choice of shear blade directly impacts the machine's performance, the longevity of the blade, and the quality of the finished product. Selecting the appropriate type of shear blade is crucial for optimizing operational efficiency and achieving desired results. Additionally, understanding maintenance needs and operational costs associated with different types of blades is vital for long-term operation. This article provides an overview of the various types of shear blades used in hydraulic shearing machines. We will delve into their descriptions, functionalities, and common applications, and discuss their advantages and disadvantages to help you make informed decisions about hydraulic shearing machine blades. Carbon tool steel blades are known for their cost-effectiveness and are best suited for light to moderate cutting tasks. Made from carbon-rich steels such as T10, T8, and 65, these blades are heat-treated to improve durability, making them a common choice in industries such as automotive and construction. These blades are well-suited for cutting ordinary low-carbon cold-rolled sheets, standard steel plates, and mild steel products, where precision cutting is needed, but the materials are not highly abrasive or high-tensile. Industries using carbon tool steel blades often process materials with moderate demands on wear resistance and cutting force, making this material ideal for small to medium-sized shearing machines. While cost-effective, carbon tool steel blades tend to have a shorter lifespan in heavy-duty applications and require regular maintenance to maintain cutting precision. This limitation can make them less suitable for high-volume or high-stress tasks but still an affordable choice for general-purpose shearing needs. Low alloy tool steel blades, incorporating elements such as chromium, silicon, and tungsten, are designed for more demanding applications, providing greater edge retention, wear resistance and toughness than carbon steel. Grades like 9CrSi, 6CrW2Si, and Cr12MoV enhance cutting efficiency, allowing these cutting blades to handle tougher materials such as hot-rolled steel, stainless steel, and medium-thickness plates with higher tensile strength. Industries like heavy machinery manufacturing, metal fabrication, and certain processing plants prefer low-alloy blades due to their ability to withstand prolonged operations without frequent replacement. Low-alloy tool steel is particularly valued in scenarios requiring consistent cutting performance under moderate to high force, such as processing thicker plates or harder metals in manufacturing lines. Although these blades require higher operational power and come with a higher initial cost, they offer extended lifespan and reliable performance in environments where longevity and toughness are prioritized over initial expense. This balance of durability and cutting strength places low-alloy steel as a durable mid-level choice for industrial shear blades. High-alloy tool steel blades are engineered for the most demanding environments, where high stress, temperature, and cutting force are required. Examples include alloys like 4Cr5MoSiV1 (H13) and W6Mo5Cr4V2, which incorporate chromium, molybdenum, vanadium, and tungsten. The material features high temperature resistance and is not easy to anneal. These elements create exceptional heat resistance, enabling high-alloy steel blades to maintain sharpness and withstand deformation even under intense operational conditions. This resilience makes them suitable for high-speed cutting and high-temperature applications, such as in steel mills, foundries, and other heavy-duty metal processing sectors where thick and tough materials, like cast iron and reinforced steel, must be consistently sheared. High-alloy tool steel blades are a preferred choice for industries with continuous and high-stress cutting operations, offering long-term cost savings despite their higher upfront cost. With extended durability, they significantly reduce the need for frequent replacements and sharpening, making them an economical option for high-intensity environments. Maintenance requirements for these blades are comparatively lower, as their resistance to wear and deformation supports prolonged performance and precision cutting. Choosing high-alloy tool steel is an investment in reliability and long-term performance, making it highly advantageous for heavy industrial use and rigorous cutting applications where blade longevity and consistency are essential. Description and Functionality Guillotine blades are characterized by their straight edge, which enables them to make linear cuts with high precision. The blade descends onto the material being cut, applying a shearing force that separates the material along a straight line. This shearing action is especially effective for cutting sheet metal, but guillotine blades are also used for other materials such as paper, plastics, and textiles. Key Features: Common Applications Guillotine blades are versatile and find applications in various industrial sectors. Here are some specific examples: Advantages and Disadvantages Advantages: Disadvantages: Manufacturing Process The manufacturing of guillotine blades involves several precision processes to ensure optimal performance: Following the guillotine’s robust capabilities, shear knives offer a more versatile cutting solution, ideal for materials ranging from thin sheets to medium-thickness metal plates. Shear knives excel in industries such as manufacturing, packaging, and textiles, where precision and adaptability are necessary. Unlike guillotine blades, shear knives are designed for smoother, controlled cuts, suitable for materials that demand clean edges and minimal distortion. These blades can handle materials like mild steel sheets under an inch in thickness, aluminum panels, and various plastic and fabric layers used in automotive and textile manufacturing. An important feature of shear knives is their adjustable sharpness, which can be fine-tuned for specific tasks. This adaptability makes them useful for producing precise cuts in materials like packaging films and lightweight metal parts. Shear knives also reduce burr formation, or unwanted rough edges, enhancing the quality of each cut. While shear knives can handle a range of materials, they are not designed for extremely thick or dense materials where more forceful blades, like guillotine blades, would be necessary. Their value lies in industries where cut quality and material integrity are essential to the final product. Description and Functionality Straight blades are characterized by their simple, linear cutting edge. They perform straight cuts by applying a uniform shearing force along a single axis, ensuring precision and consistency in straight-line cutting. Key Features: Common Applications Straight blades are widely utilized across numerous industries due to their versatility and dependability. Here are some specific examples illustrating their use: Advantages and Disadvantages Advantages Disadvantages In contrast to the stationary nature of guillotine and shear knives, rotary blades are engineered for continuous, high-speed cutting, especially in environments that require repetitive, rapid cuts. Rotary blades spin as they cut, making them a prime choice for production lines where materials like textiles, paper, or packaging films need to be cut into specific shapes or lengths. Their rotational motion allows for swift and consistent cuts, making them ideal for high-output applications such as in roll-forming machines and rotary shearing equipment. Rotary blades are especially valued in automated settings, where maximizing productivity is critical. However, the constant rotational motion means these blades experience frequent contact with materials, leading to a faster rate of wear. Consequently, rotary blades require regular maintenance or replacement, especially in high-demand settings. While they are not suitable for thicker or highly resistant materials, their efficiency in cutting lighter materials at high speeds is unmatched. Rotary shearing, or cutting via rotation, is well-suited for precision tasks in packaging, textile processing, and paper industries, where the priority is on speed and repetitive accuracy. Each blade design—guillotine, shear, and rotary—offers unique strengths tailored to specific industrial applications, optimizing performance for different materials and operational needs. These designs not only enable efficient and accurate cuts but also reflect ongoing innovations in blade technology that enhance productivity across diverse industrial contexts. The flat-edge shear blade, or "90° edge," features a perpendicular cutting angle. This design excels in heavy-duty applications where significant force is needed to shear through thick or hard materials. The 90° angle provides a stable cutting surface that resists deformation under pressure, making it ideal for robust cutting tasks. The oblique-edge shear blade, typically angled at 82°, is designed for smooth, precise cuts. This edge type reduces cutting resistance and creates cleaner edges, especially in thinner or softer materials. The oblique design allows for controlled, refined cuts, beneficial in applications where edge quality is crucial. Razor blades are precision tools crafted for cutting thin, lightweight materials with high accuracy, crucial in industries where smooth, burr-free edges are necessary. These ultra-sharp blades excel in applications requiring meticulous detail, such as cutting paper, plastic films, textiles, and delicate foils, where clean cuts ensure material quality and reduce processing times. Scissor blades are versatile tools for handheld or automated use, suitable for cutting lightweight, flexible materials with high control. Equipped with serrated or micro-serrated edges, they grip the material firmly, reducing slippage and enhancing precision during manual operations—ideal for intricate designs and complex cuts in various industries. Notched and serrated blades are designed to provide additional grip and stability for materials that resist smooth cuts. With edges that feature notches or serrations, these blades make effective contact points, ensuring that the material remains steady during cutting. This is particularly advantageous in handling materials prone to slipping or shifting, making these blades ideal for cutting uneven or fibrous materials. Tungsten carbide-coated blades are engineered for demanding tasks, providing exceptional durability and wear resistance. Known for their hardness, these blades withstand high-stress environments and maintain sharpness over prolonged use, making them indispensable for heavy-duty applications. Slotted blades and custom razor blades are tailored for specialized applications, providing high-precision solutions for unique industrial requirements. Slotted blades, featuring small slots or perforations, allow flexible installation in machinery and perform specific cutting actions that align with particular production needs. Selecting the appropriate shear blade is crucial, as it directly influences the efficiency, precision, and sustainability of cutting operations. A thorough understanding of your specific needs, meticulous maintenance, and a commitment to staying updated on the latest technological advancements will ensure optimal performance and long-term success in various industrial applications. By adopting new technologies and materials, industries can achieve superior cutting results, extend the lifespan of their blades, and maintain a competitive edge in an ever-evolving market. In conclusion, the right shear blade is more than just a tool; it is a critical component that significantly impacts the efficiency, quality, and sustainability of cutting operations. Making informed decisions about blade selection, maintenance, and adoption of new technologies will ensure optimal performance and long-term success. Rotary blades are not universally suitable for all hydraulic shearing machines. They are primarily designed for continuous cutting in specific applications, such as roll-forming machines and rotary shearing equipment, where they cut materials into defined shapes and lengths. Most hydraulic shearing machines, like guillotine shears and power shears, require a different cutting action, typically using fixed upper and lower blades rather than rotary ones. Additionally, the material type and thickness are crucial considerations: rotary blades can manage continuous cuts on certain materials, but thicker or harder metals often require the strength and precision of fixed blades in hydraulic shears. Consequently, rotary blades are limited to specific machine designs and applications, making them unsuitable for general-purpose plate shearing across all hydraulic machines. Zinc Casting,Auto And Motorcycle Parts,Auto Motorcycle Parts,Communication Product,Integrated Die Casting Products,Aerospace Parts Dongguan Yurun Hardware Products Co., Ltd , https://www.yurunhwfty.comI. Introduction

II. Types of Shear Blades

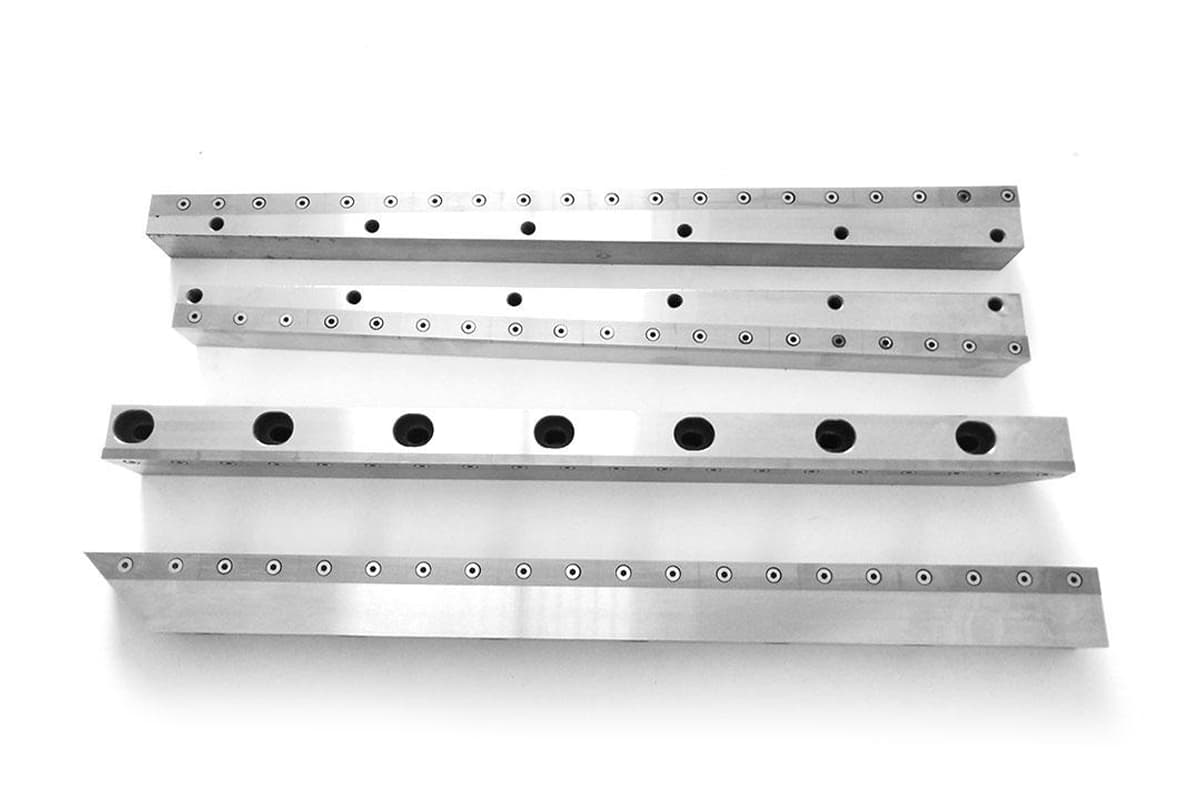

1. Blade Material -Based Classification

Carbon Tool Steel

Low-Alloy Tool Steel

High-Alloy Tool Steel

2. Design and Application-Based Classification

Guillotine Blades

Shear Knives

Straight Blades

Rotary Blades

Comparison of Different Types of Metal Shear Blades

Blade Type Primary Use Cutting Method Applicable Materials Straight Blades Precise straight cuts Direct pressure Metal, paper, etc. Shear Knives Multi-purpose metal and non-metal cutting Shearing Metal sheets, plastics Guillotine Blades Heavy material cutting Vertical downward pressure Thick metals, plastics Rotary Blades Continuous rapid cutting Rotation Long strip materials 3. Edge Type-Based Classification

Flat Edge (90°)

Oblique Edge (82°)

4. Designed for Specific Cutting Profiles

Razor Blades

Scissor Blades

Notched and Serrated Blades

Tungsten Carbide-Coated Blades

Slotted and Custom Razor Blades

III. Conclusion

IV. FAQs

1. What are the main differences between guillotine blades and shear knives?

Aspect Guillotine Blades Shear Knives (Swing Beam Shears) Cutting Mechanism Linear motion – upper blade moves straight up and down Circular arc motion Precision High precision with controlled blade clearance, providing smooth edges with minimal burrs Less precision due to larger blade clearance and alignment variations Cutting Angle Adjustable, reduces material twisting and deformation Fixed, more prone to material twisting, especially with thin or narrow materials Blade Longevity Longer lifespan due to four-sided cutting on both blades Shorter lifespan with two-sided cutting Maintenance More complex, requires higher maintenance Simpler structure, easier to maintain Cost Higher cost due to complexity Lower cost, making it more cost-effective Application Suitability Ideal for precision-focused tasks with varying material thicknesses Suitable for straightforward tasks, particularly with thicker steel plates, where precision is secondary 2. Are rotary blades suitable for all types of hydraulic shearing machines?