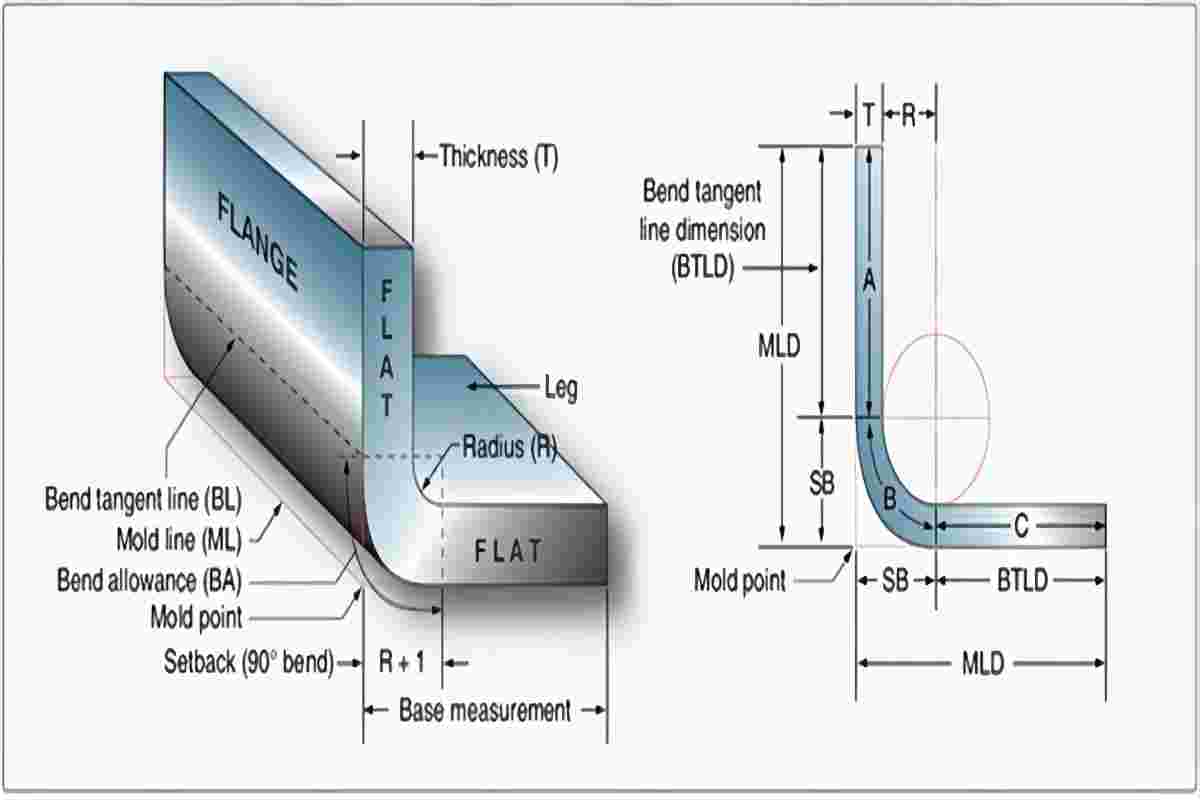

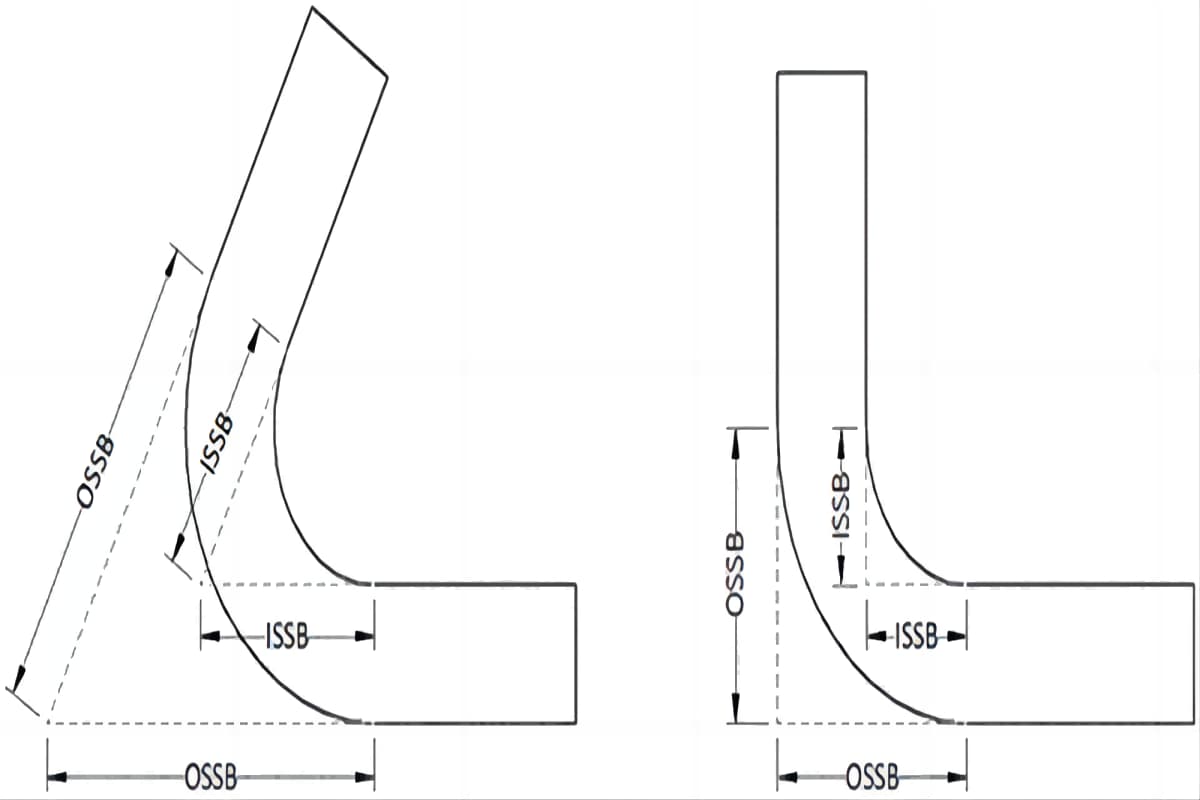

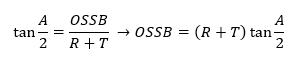

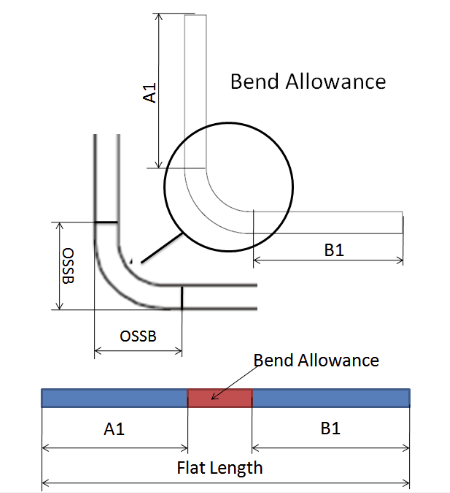

In the world of sheet metal fabrication, understanding the concept of sheet metal setbacks is crucial for achieving precise bends and high-quality results. This guide will delve into the definition of sheet metal setback, its calculation methods, and related terms, providing you with the knowledge needed to excel in your metalworking projects. Before understanding the sheet metal setback, it is important to be familiar with the definitions of the mould line and bend line: Sheet metal setback refers to the distance from the bend line to the point where the metal starts to bend. It is also described as the difference between the mold line length and the flange length. Also is a crucial factor in sheet metal fabrication. In a 90-degree bend, the setback value is equal to the bend radius plus the thickness of the metal sheet. By knowing the setback size, we can determine the bending tangent position of the workpiece. The setback plays a crucial role in workpiece design. If the workpiece needs to be bent multiple times, the setback must be subtracted for each bend. It is important to note that the bend allowance and bend deduction can change based on changes in the K factor value, but the setback remains constant regardless of changes in the K factor. The k-factor is the ratio between the thickness of the metal being bent and something called the “neutral axis/line.†To accurately calculate the sheet metal setback, you need to consider several factors, including the material thickness, bend radius, and bend angle. Both the inside and outside setback formulas take into account only the geometries of bending rather than the physical properties of the metal. The formula for calculating setback is: Outside Setback (OSSB) =Tan (A/2) × (T+R) Where A is the bend angle, T is the sheet thickness, and R is the inside bend radius. The above video is the setback formula. Additional factors such as the K-factor and bend allowance may need to be included in the calculation for more complex bends. The setback is divided into two types: inside setback and outside setback. The bend angle and radius are the factors affecting the setback: Bend allowance is the length of the neutral axis between the bend lines, which accounts for the material stretching during the bending process. The formula for bend allowance is: And you can browse here to see the Sheet Metal Bending Calculator. Bend deduction is the amount subtracted from the total length of the flat sheet to achieve the desired final dimensions after bending. The formula for bend deduction is: BA(Bend Allowance)=2OSSB-BD(Bend Deduction) The outside setback can be calculated by the following formula The sum of bend deduction and bend allowance is equal to two times the outside setback. This can be expressed as T (sheet thickness) + A (bend angle) + R (inside bend radius). For a 90° bend angle, the setback value is equal to the bend radius plus the sheet thickness. When the bend angle is less than 90°, the complementary angle is usually used, and when the bend angle is greater than 90°, the included angle or complementary angle is usually used. Let's consider a practical example to illustrate these concepts. Suppose you have a sheet metal piece with a thickness of 2mm, a bend radius of 5mm, and a bend angle of 90 degrees. Using the formulas provided: Setback: 5mm+2mm=7mm Bend Allowance: Bend Deduction: The bend radius is the distance from the bend axis to the inner surface of the sheet, generally referring to the inner radius. The value of the outside radius is equal to the inner radius plus the sheet metal thickness. The smaller the radius, the higher the tension and compression on the material. The size of the radius is determined by the metal material's properties such as tensile strength, ductility, thickness, and the size of the die opening. As a general rule, the larger the die opening size, the larger the radius. Understanding and accurately calculating sheet metal setback is essential for precise and efficient metalworking. This blog introduces the definition, calculation method, and related terms of the setback in sheet metal bending. The setback is a crucial aspect of workpiece design and has close connections with the k-factor in sheet metal bending, bend allowance, bend deduction, and other factors, which can help you manually modify a flat pattern to obtain the correct finished part size. The setback is only considered in angles up to about 170 °. However, if the bend angle approaches 180°, the values of the inside and outside setbacks don't have to be considered because the setback value becomes close to infinity and the bend is nearly flat. At ADH, we are dedicated to the design and manufacture of sheet metal machines, including press brakes and laser cutting machines. Contact us today for a free consultation or download our comprehensive guide on sheet metal bending to learn more. Transparent powder coating,Resin,Transparent HLM Powder Coating CO,.Ltd , https://www.holymepowder.comI. Introduction

II. What Is Sheet Metal Setback?

III. Calculating Sheet Metal Setback

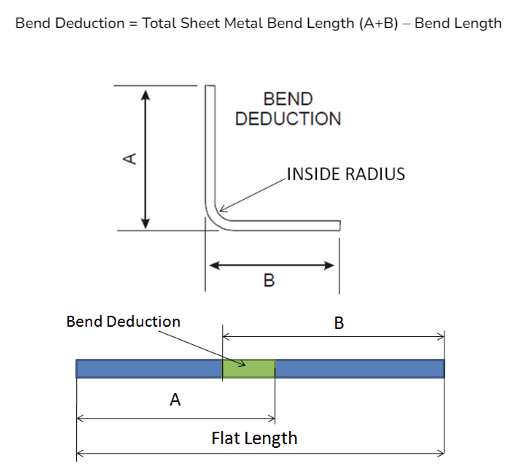

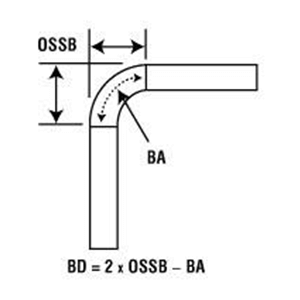

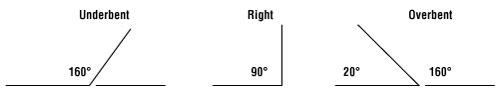

IV. Bend Allowance and Bend Deduction

1. Bend Allowance

2. Bend Deduction

3. Practical Calculating Bend Example

V. What Is the Sheet Metal Bend Radius?

1. Bend Allowance Chart

2. Bend Deduction Chart

VI. Conclusion