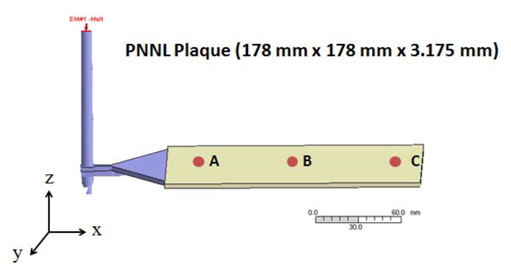

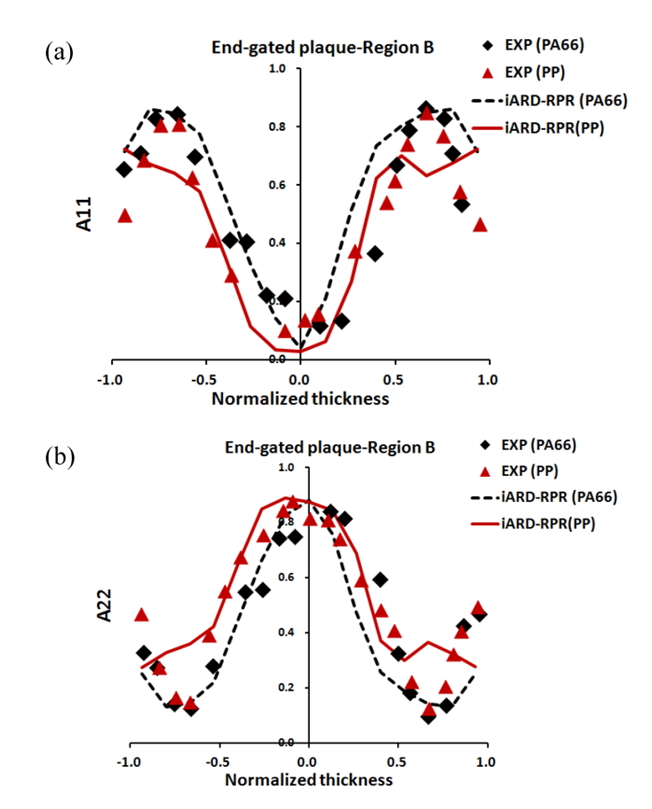

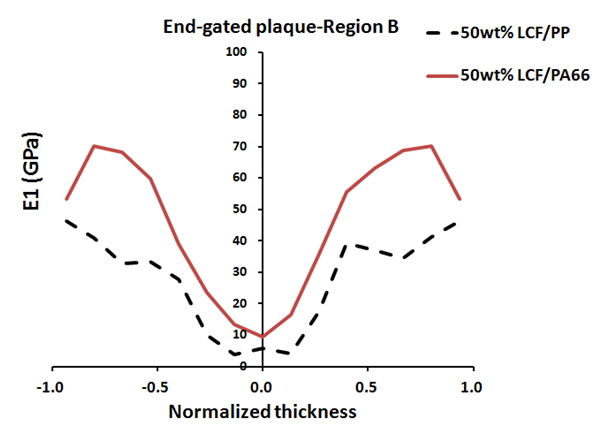

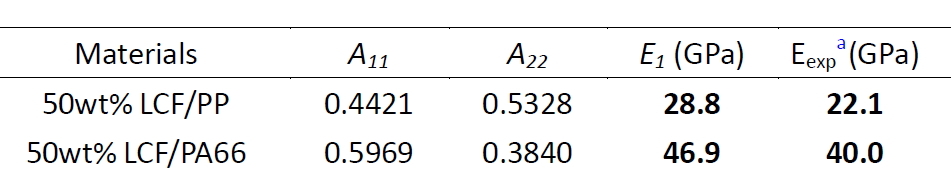

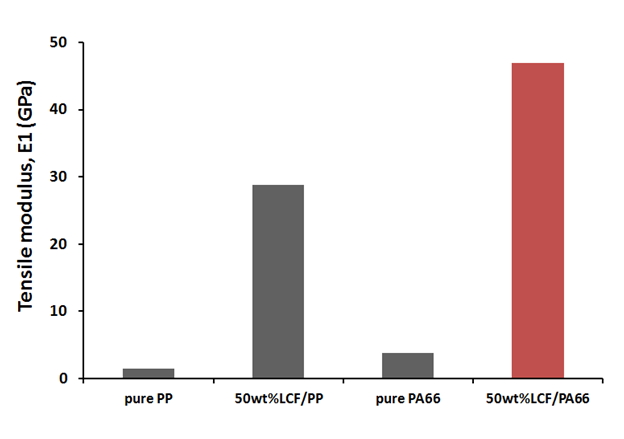

Long carbon fiber reinforced thermoplastics (LCFRT) have become familiar lightweight automotive materials since they satisfy safety and durability requirements, and the mechanical performance characteristics of carbon fibers are superior to those of glass or natural fibers. In practice, a typical laminate structure, shell-core, is observed in the injection molded FRT parts. Long fibers’ anisotropic orientation strongly influences the enhanced mechanical properties of an FRT product. However, predicting anisotropic orientation is a challenge in dealing with longer fibers and higher fiber concentrations.  So far, only a few attempts have been made to probe the changes of fiber orientation for various fiber composites from a simulation point of view. Two polymer matrices, polypropylene (PP) and polyamide 6,6 (PA66), are considered in the present study.  The materials of interest are long carbon fiber (LCF) reinforced thermoplastic composite, including 50wt% LCF/PP and 50wt% LCF/PA66. The end-gated plaque of mold filling is illustrated in Fig. 1. The plaque dimensions were 178mm x 178mm x 3.175mm. Different from the past method, the Moldex3D’s model iARD-RPR has only three parameters to accurately predict fiber orientation in injection molding simulation.  Fig. 2 shows the fiber orientation distribution through the thickness at the center of the PNNL (Pacific Northwest National Laboratory) plaque (Region B, the middle of the plaque) for 50wt%LCF/PP and 50%LCF/PA66.  Overall, the iARD-RPR predictive results matched the experimental data very well. A micromechanical material modeling software, Digimat-MF (MSC Software & e-Xstream engineering), based on the Mori-Tanaka Mean Field homogenization scheme, was used to compute the mechanical performance of the fiber-reinforced thermoplastic composites. Based on the predicted fiber orientation data, we applied Digimat-MF to obtain the flow modulus E1.  Consequently, the modulus distribution through the normalized thickness is presented in Fig. 3.  We further made a comparison of modulus E1 to find: 50wt% LCF/PA66 > 50wt% LCF/PP.  The thickness-averaged modulus E1 value are listed in Table 1, and compared with the experimental data. Roughly, the predicted E1 value is satisfied.  Under adding the same fiber concentration of 50wt% LCFs, the reinforcing performance for the PA66 composite is more effective than the PP composite, as shown in Fig. 4. Table 1. The thickness-averaged orientation tensor components (A11 and A22) and tensile moduli (E1) at Region B of the end-gated plaque for different materials with the experimental bulk value of tensile modulus (Eexp). In summary, an accurate prediction of fiber orientation is now available in the integrative simulation of Moldex3D and Digimat-MF computation for real automotive LCFRT products, and the structural strength can be further assured.  Since the complex geometry of designing high-quality parts involves various changes in the direction of the flow, the inclusion of ribs and the changes in the thickness and holes, discovering how to determine the optimal parameters of the fiber orientation model is a critical goal for ongoing and future research. Canvas Tote Bag,High-Cost Performance Canvas Bag,Printed Promotional Canvas Tote Bags,Colorful Canvas Stationery Pencil Bag Guangzhou Ecobag Packaging Co., Ltd , https://www.gdecobag.comRef. Tseng H-C, Chang R-Y, Hsu C-H. Numerical predictions of fiber orientation and mechanical properties for injection-molded long-carbon-fiber thermoplastic composites. Polymer Composites 2017, First Published, https://onlinelibrary.wiley.com/doi/10.1002/pc.24403/abstract

Ivor Tseng

Fig. 1 Illustration of injection molded geometry for the PNNL plaque with three measured regions.

Fig. 1 Illustration of injection molded geometry for the PNNL plaque with three measured regions. Fig. 2 A comparison of the 50wt% LCF/PA66 and 50wt% LCF/PP composites with the PNNL experimental data and the iARD-RPR curves for orientation components, (a) A11 and (b) A22, through the normalized thickness at Region B measured in the end-gated plaque.

Fig. 2 A comparison of the 50wt% LCF/PA66 and 50wt% LCF/PP composites with the PNNL experimental data and the iARD-RPR curves for orientation components, (a) A11 and (b) A22, through the normalized thickness at Region B measured in the end-gated plaque. Fig. 3 The predicted tensile moduli E1 distribution through the normalized thickness at Region B measured in the end-gated plaque for various fiber composites, 50wt% LCF/PP and 50wt% LCF/PA66.

Fig. 3 The predicted tensile moduli E1 distribution through the normalized thickness at Region B measured in the end-gated plaque for various fiber composites, 50wt% LCF/PP and 50wt% LCF/PA66. aTaken from Web Page of PlastiComp Technical Data Sheet.

aTaken from Web Page of PlastiComp Technical Data Sheet. Fig. 4 Bar chart of the predictive tensile modulus against various fiber composites with experimental data of pure PP and pure PA66.

Fig. 4 Bar chart of the predictive tensile modulus against various fiber composites with experimental data of pure PP and pure PA66.

Dr. Huan-Chang (Ivor) Tseng

Program Manager at the R&D Division of CoreTech System (Moldex3D)Ivor Tseng has a doctoral degree of Chiao Tung University, Taiwan. He majors in polymer rheology, polymer composite materials processing and molecular simulation. His brand new theoretical model, “Method and Computer Readable Media for Determining Orientation of Fibers in a Fluidâ€, has received United States Patent. His paper entitled “An Objective Tensor to Predict Anisotropic Fiber Orientation in Concentrated Suspensions†has also been published by Journal of Rheology®, one of the most important leading publications in Rheological Fundamentals of Polymer Processing.