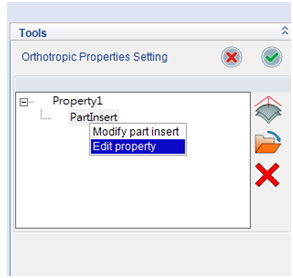

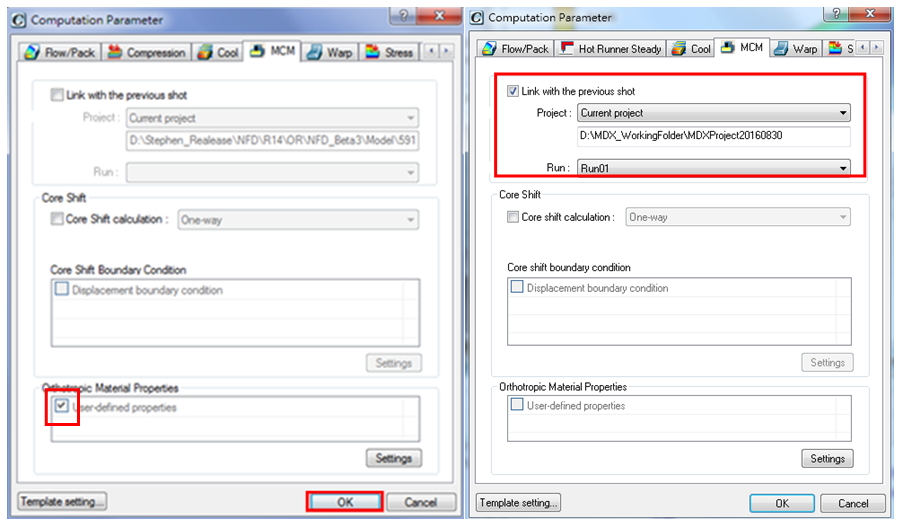

The draping process will change the fiber orientation of the orthotropic prepreg, and further affect its mechanical property and warpage behavior. Moldex3D Multi-component module (MCM) module supports orthotropic material setting of part inserts and allows users to consider the effect of the previous shot. Applying project method or existing orthotropic material data, the mechanical property affected by the orientation of continuous fiber in the prepreg can be considered in details in the simulation. Step 1. To assign orthotropic material of the part insert, go to MCM tab in Computation Parameter of the MCM project. Under the tab, click Settings under Orthotropic Material Properties to launch the workspace and assign or modify the orthotropic material property. The option, User-defined properties will show up if any orthotropic material has been assigned. Step 2. In the workspace, users can create orthotropic material data to part insert. Click Step 3. Click Step 4. For two-shot molding, users can use the same orthotropic material setting on the same prepreg insert for the second shot. Under MCM tab in Computation Parameter, check Link with previous shot and specify the project and run number as the resource of part insert data from the previous shot. Parallel Twin Screw Barrels,Injection Moulding Screw Barrel Design,Types of Screw Barrel ZHEJIANG BOHAI MACHINERY CO., LTD , https://www.bohai-screw.com

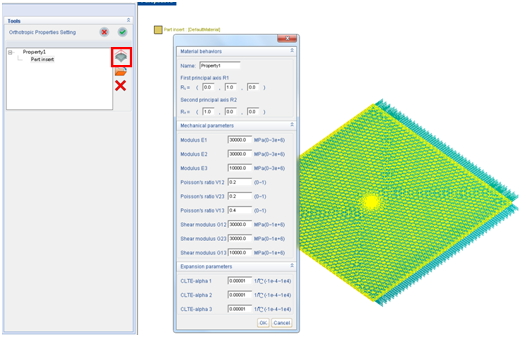

![]()  Create property and select the target part insert mesh, and specify the property name and two directions of principle axis. By expanding the dialog, users can modify mechanical and expansion parameters in each axis direction.

Create property and select the target part insert mesh, and specify the property name and two directions of principle axis. By expanding the dialog, users can modify mechanical and expansion parameters in each axis direction.

Note: The principle axis is the two main orientations of the part insert material before prepreg.

![]()  Import property, select target material data, and select a part insert mesh to assign it.

Import property, select target material data, and select a part insert mesh to assign it.![]()  Delete property and select a property item to remove it.

Delete property and select a property item to remove it.

![]()  to go back to Project. User-defined properties will be checked. Then, click OK to finish the settings and run analysis.

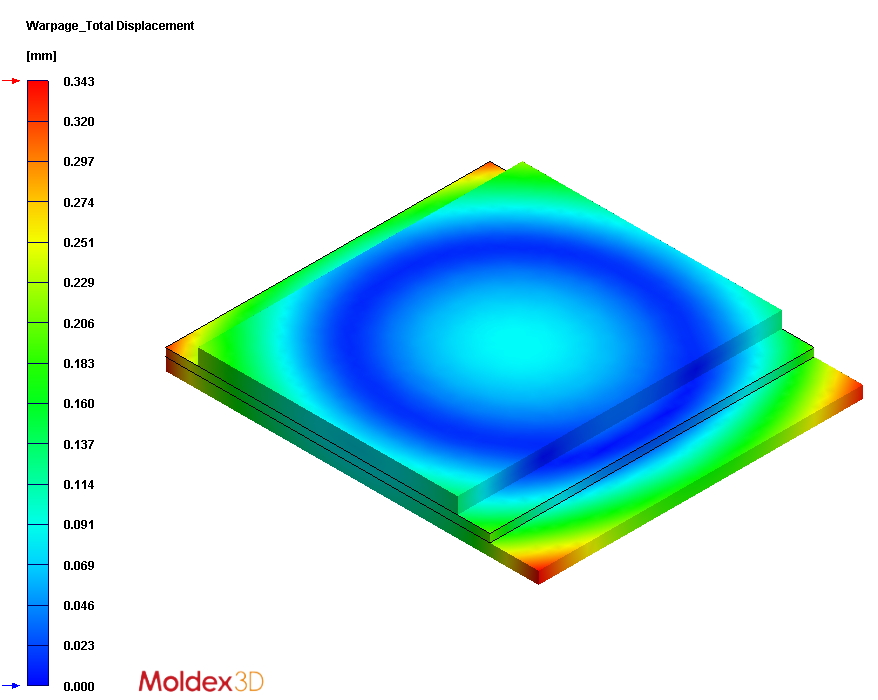

to go back to Project. User-defined properties will be checked. Then, click OK to finish the settings and run analysis. Two-shot molding warpage analysis result

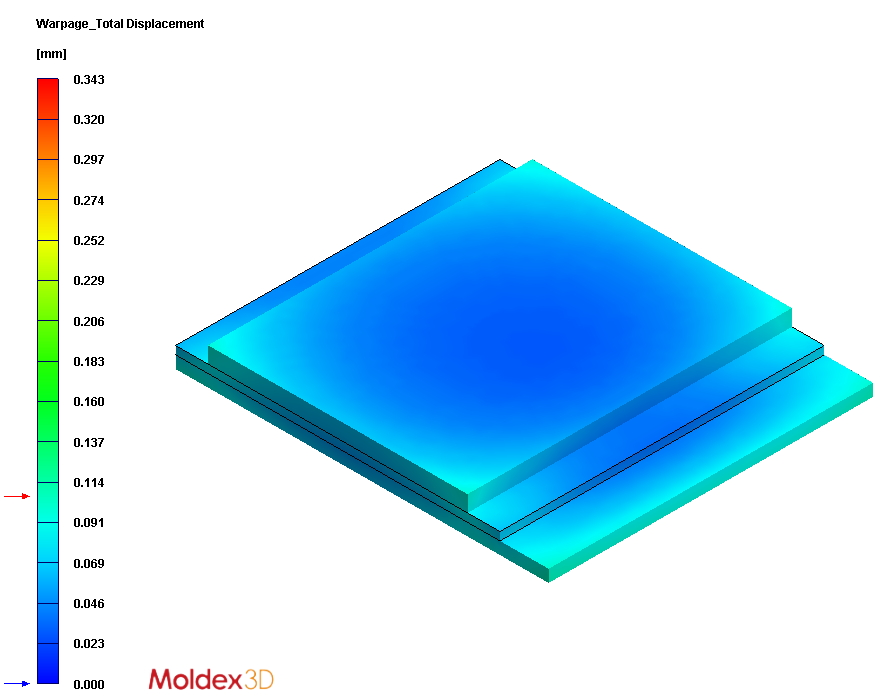

Two-shot molding warpage analysis result               Â

Â Â Â Â Â Â Â Â Â Â

Link with the previous shot                    No link with the previous shot